PE, PI, PET, PP and other flexible/non-metallic materials are also widely used in the medical field.

Ultrafast laser, with its extremely short pulse width, can achieve precise control of heat input during the processing. This characteristic is particularly prominent in flexible/non-metallic material cutting and drilling operations, which can effectively avoid adverse phenomena such as melting, yellowing, or blackening of material processing edges.

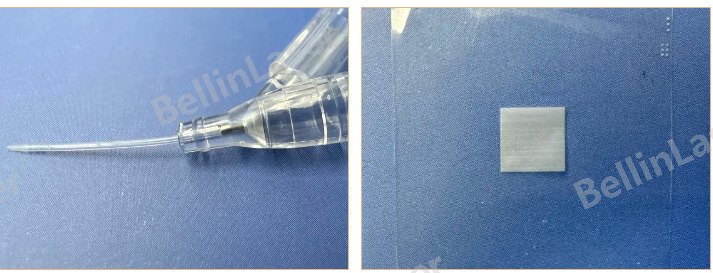

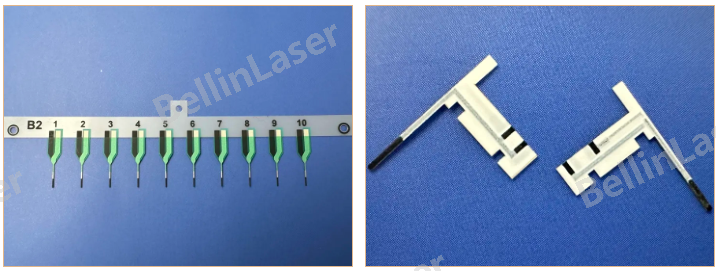

In application scenarios such as polymer stent cutting, dialysis catheter cutting and drilling, indwelling needle tube drilling, and blood glucose meter electrode cutting, ultrafast laser technology has demonstrated excellent performance and processing effects, providing more refined and efficient solutions for medical product manufacturing.

Resin needle tube punching PET drilling

PET cutting PET cutting

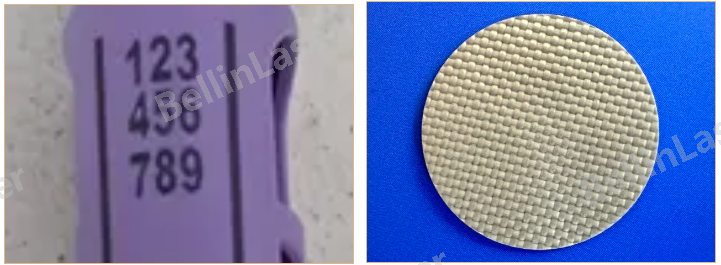

Marking on PP plastic Teflon cutting

In addition, ultrafast lasers are used for precision marking of medical devices such as catheters, medication bottles, containers, and films. They can clearly and accurately mark the name, batch number, and barcode (or QR code) on the product, which not only improves the legibility of information but also facilitates product traceability and management.

Marking on PP plastic Marking on film